Understanding Industrial Coding

Industrial coding encompasses the various methods and technologies used to print essential information on products and packaging. This can include barcodes, batch numbers, expiration dates, and other identifiers. The primary goal is to ensure that each product is accurately tracked and easily identifiable throughout its lifecycle.

Industrial coding ensures compliance with regulatory standards, facilitates efficient inventory management, and enhances product safety. Whether it’s pharmaceuticals, food and beverages, or consumer goods, industrial coding is integral to maintaining the integrity and traceability of products.

Types of Industrial Coding Technologies

Several advanced technologies drive the efficiency and precision of industrial coding. Each method has unique advantages tailored to specific applications and industry needs.

Inkjet Printing

Inkjet printing is one of the most versatile and widely used methods in industrial coding. This technology works by propelling droplets of ink onto the surface of products or packaging.

The benefits of inkjet printing are numerous. It offers high-speed printing, the ability to print on various surfaces, and the flexibility to produce detailed text and graphics. Its applications range from printing expiration dates on food packages to coding electronic components.

Laser Coding

Laser coding offers a durable and permanent solution for high-quality marking. This method uses a focused laser beam to etch or engrave information onto the product’s surface.

The advantages of laser coding include its ability to produce high-resolution marks that are resistant to wear and tear, making it ideal for industries requiring long-lasting codes. Common uses include marking glass bottles, metal components, and plastic packaging.

Thermal Transfer Overprinting (TTO)

Thermal Transfer Overprinting (TTO) is a reliable method for printing high-resolution barcodes and text. It involves transferring ink from a ribbon onto the substrate using heat and pressure.

TTO technology is known for its precision and the ability to print variable data, making it perfect for applications such as printing batch numbers on pharmaceutical packaging and barcodes on retail labels.

Advantages of Industrial Coding

Industrial coding offers numerous advantages that significantly impact production efficiency and product integrity. Enhanced traceability and product safety are among the top benefits. By enabling accurate tracking of products from manufacture to end-user, industrial coding helps prevent counterfeiting and ensures that only safe, compliant products reach consumers.

Additionally, industrial coding improves inventory management by providing real-time data on product movement and stock levels. This leads to more efficient logistics and reduces the risk of stockouts or overstocking. Compliance with industry regulations and standards is another critical advantage, ensuring that products meet all necessary legal requirements.

Furthermore, industrial coding reduces errors and waste by automating the marking process and minimising manual interventions. This leads to higher production accuracy and consistency.

The Role of Wolke Thermal Inkjet Printers

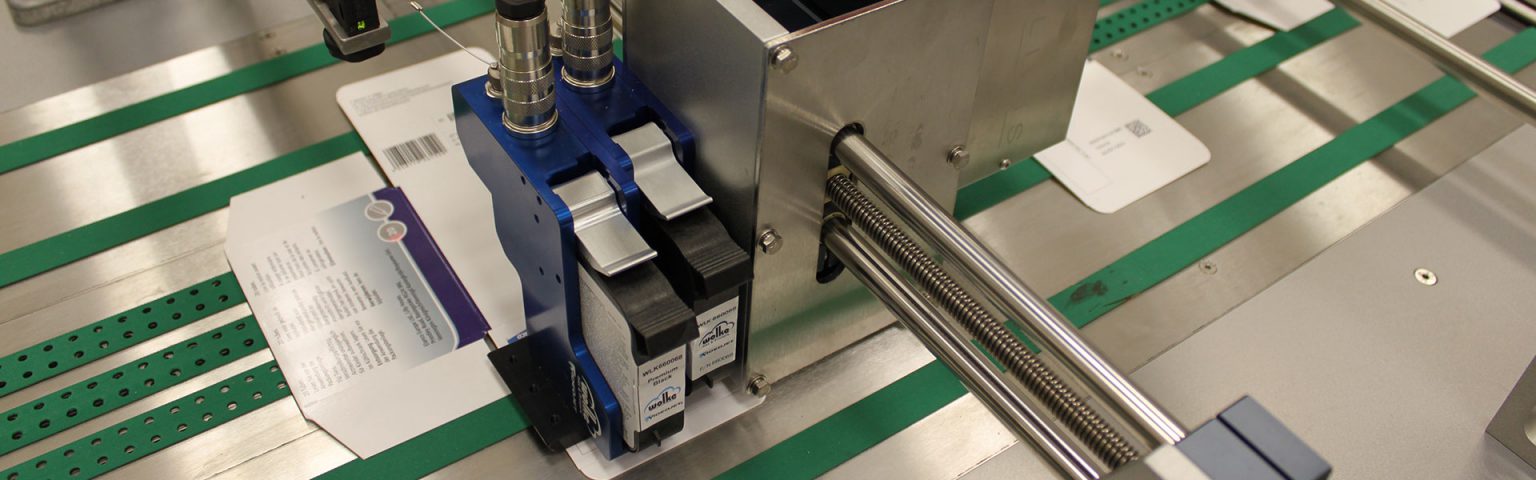

At Sunala, we specialise in Wolke Thermal Inkjet Printers, renowned for their precision and reliability. These printers are designed to meet the demanding needs of various industries, providing high-quality, durable codes.

Wolke Thermal Inkjet Printers utilise advanced technology to deliver sharp, clear prints at high speeds. Their features include easy integration with existing production lines, low maintenance requirements, and the ability to print on various substrates. Real-world applications include coding on pharmaceutical blister packs, food packaging, and electronic components.

The choice of Wolke Thermal Inkjet Printers is driven by their ability to provide consistent, high-quality results, ensuring that our clients’ coding needs are met with the highest standards of reliability and efficiency.

Implementation of Industrial Coding Solutions

Implementing an effective industrial coding solution requires careful planning and consideration of several factors. The first step is assessing your specific coding needs. This involves understanding the type of products being coded, the required information, and the production environment.

Choosing the right technology and equipment is crucial. Factors to consider include the type of substrate, the speed of the production line, and the desired print quality. Integration with existing production lines is another important aspect. Ensuring that the new coding system works seamlessly with your current setup can minimise disruptions and maximise efficiency.

Training and maintenance are essential for optimal performance. Providing your team with the necessary training ensures they can operate and maintain the equipment effectively. Regular maintenance and updates keep the system running smoothly and prevent costly downtimes.

Challenges in Industrial Coding

Despite its numerous benefits, industrial coding can present certain challenges that need to be addressed. Common issues include equipment malfunctions, poor print quality, and difficulties in maintaining consistent coding standards.

Solutions and best practices to overcome these challenges include regular equipment maintenance, using high-quality consumables, and implementing stringent quality control measures. Staying updated with the latest technological advancements and industry trends can also help mitigate potential issues.

The importance of regular maintenance and updates cannot be overstated. Keeping your equipment in top condition ensures reliable performance and extends its lifespan, reducing the need for frequent replacements.

Embracing the Future of Industrial Coding

Industrial coding is an indispensable component of modern manufacturing and packaging, ensuring efficiency, traceability, and compliance. As we’ve explored, the various technologies, advantages, and future trends all contribute to its critical role in the industry.

Sunala stands at the forefront of this field, offering cutting-edge coding solutions with a special emphasis on Wolke Thermal Inkjet Printers. Our commitment to quality and innovation ensures that our clients receive the best possible service and products.

If you’re looking to enhance your industrial coding capabilities, we encourage you to reach out to Sunala for expert advice and tailored solutions that meet your specific needs.