Packaging Machinery

Packaging machinery plays a crucial role in ensuring products are packaged swiftly and accurately. At Sunala, we pride ourselves on providing top-tier packaging and coding solutions, including conveyor accessories, labelling machines, and product feeders.

Packaging Machinery By Sunala

Packaging machinery encompasses a wide range of equipment designed to streamline the packaging process, from filling and sealing to labelling and coding. These machines automate repetitive tasks, ensuring that products are packaged consistently and efficiently. By reducing the need for manual labour, packaging machinery not only increases productivity but also minimises errors and waste.

The scope of packaging machinery is vast, covering everything from small tabletop units for start-ups to large-scale systems for industrial use. Industries such as food and beverage, pharmaceuticals, cosmetics, and consumer goods all rely on various types of packaging machinery to maintain their production lines.

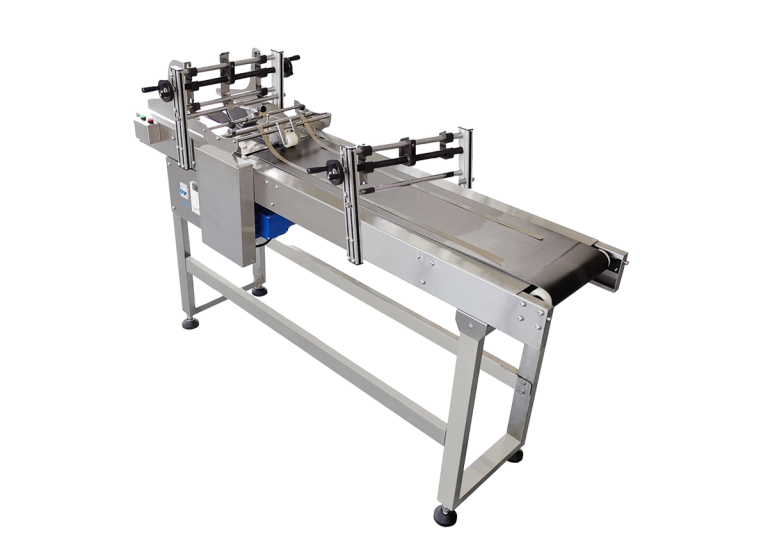

Conveyor Systems

Conveyor systems are the backbone of many packaging lines, ensuring smooth and efficient movement of products. These systems come in various forms, including belt, roller, and chain conveyors, each suited to different types of products and production environments.

Conveyors are essential for maintaining a steady flow of products through the packaging process. They reduce manual handling, increase speed, and improve overall efficiency. For example, belt conveyors are ideal for transporting lightweight items, while roller conveyors are better suited for heavier products.

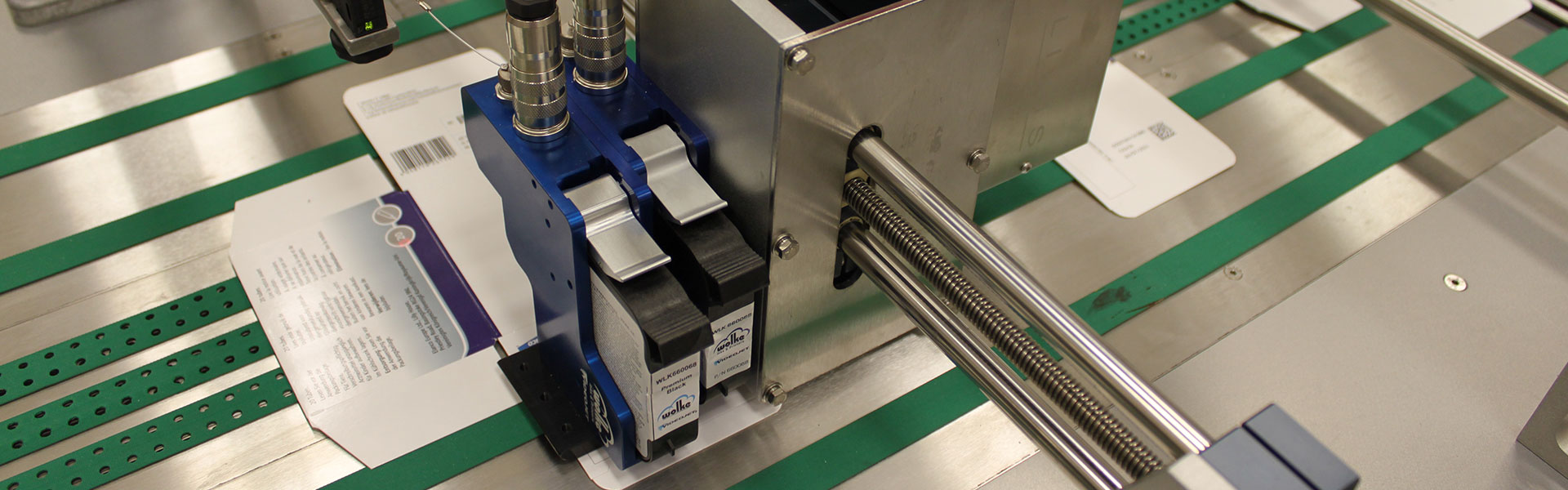

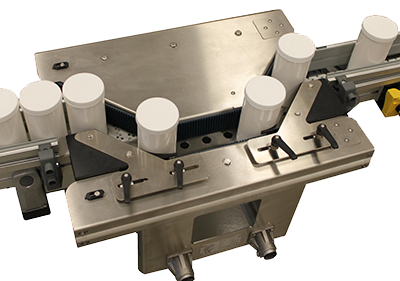

Labelling Machines

Labelling machines are essential for applying labels accurately and efficiently on products. Various labelling technologies are available, including pressure-sensitive, heat-shrink, and in-line labelling machines. Each type has its own set of advantages and is suited to different applications.

Pressure-sensitive labelling machines apply adhesive labels to products, making them ideal for flexible packaging. Heat-shrink labelling machines use heat to shrink labels tightly around the product, providing a secure and tamper-evident solution. In-line labelling machines are integrated into the production line, allowing for seamless labelling as products move through the packaging process.

Product Feeders

Product feeders play a crucial role in maintaining a consistent supply of products to the packaging line. Different feeding mechanisms, such as vibratory, centrifugal, and gravity feeders, ensure that products are fed into the packaging machine at a steady rate.

Vibratory feeders use vibrations to move products along a track, making them suitable for small, lightweight items. Centrifugal feeders use centrifugal force to sort and feed products, ideal for high-speed applications. Gravity feeders rely on the force of gravity to move products, providing a simple and cost-effective solution for certain types of products.

Trusted Worldwide

Technology in Packaging Machinery

Modern packaging machinery leverages advanced technology to enhance precision, speed, and flexibility. Automation and digitalisation have revolutionised the packaging industry, enabling manufacturers to achieve higher levels of efficiency and accuracy.

Automation reduces the need for manual intervention, allowing packaging lines to operate continuously and with minimal supervision. This leads to increased throughput and reduced labour costs. Digitalisation, on the other hand, enables real-time monitoring and control of packaging processes. Advanced sensors and software ensure that every aspect of the packaging operation is optimised for maximum efficiency.

Benefits of Using Our Packaging Machinery

Investing in high-quality packaging machinery offers numerous benefits that extend beyond mere operational efficiency. Here are some of the key advantages:

Increased Productivity

High-quality packaging machinery can significantly boost productivity by automating repetitive tasks. This allows your workforce to focus on more strategic activities, while the machinery handles the routine tasks. The result is a more efficient production line that can meet higher demand without compromising on quality.

Enhanced Product Quality

Advanced machinery ensures consistent and accurate packaging, enhancing overall product quality. By maintaining uniformity and reducing errors, high-quality packaging machinery helps ensure that every product meets the same high standards. This is particularly important in industries where product consistency is crucial, such as pharmaceuticals and food and beverage.

Cost Efficiency

While the initial investment in high-quality packaging machinery may be substantial, the long-term cost savings are considerable. Automation reduces labour costs, and the precision of modern machinery minimises material waste. Additionally, the durability and reliability of high-quality machinery mean fewer breakdowns and lower maintenance costs, further contributing to cost efficiency.

Compliance and Safety

Modern packaging machinery helps businesses comply with industry regulations and safety standards. Features such as automated quality checks and tamper-evident packaging ensure that products meet all necessary compliance requirements. Moreover, advanced safety features protect workers, reducing the risk of accidents and ensuring a safer working environment.

Get Started With Sunala Packaging Machinery

For more information on how Sunala can help elevate your packaging processes, we encourage you to reach out to our team. Our experts are ready to assist you in selecting the best machinery to optimise your production line.