Efficient stock control can make or break your bottom line. While in-line coding and labeling solutions can be effective for high-volume operations, many businesses find that offline coding offers the flexibility and scalability they need—especially for smaller runs, seasonal peaks, or specialized product lines. Here’s why you should consider going offline for your case labeling and coding needs and how the CaseFeeder 2 can help streamline this process.

1. Why Offline Labelling Is a Game-Changer

- Increased Flexibility: Offline systems allow you to run smaller batches without disrupting your main production line. This is a huge advantage if you frequently switch between different case sizes or cater to varied product SKUs.

- Reduced Bottlenecks: By handling coding tasks separately, you avoid bottlenecks on your primary line. This is particularly valuable when large orders or last-minute changes come through.

- Improved Accuracy: It’s easier to maintain focus on label integrity and code placement when it’s done off-line. You can verify that every label and code meets quality standards before the case re-enters your supply chain.

2. Enhancing Stock Control Through Accuracy and Traceability

Properly labeled and coded cases are vital for stock control. With offline coding:

- Real-Time Tracking: Accurate labeling ensures your inventory management system always knows exactly which products are on hand, in transit, or awaiting dispatch.

- Reduced Errors: Mislabeled or missing codes lead to confusion, delays, and potential waste. By labeling away from the hustle of the production line, you minimize distractions and improve overall accuracy.

- Streamlined Compliance: For regulated industries, such as food and beverage or pharmaceuticals, having correct product information, lot numbers, and barcodes is non-negotiable. An offline coding solution helps you meet these requirements seamlessly.

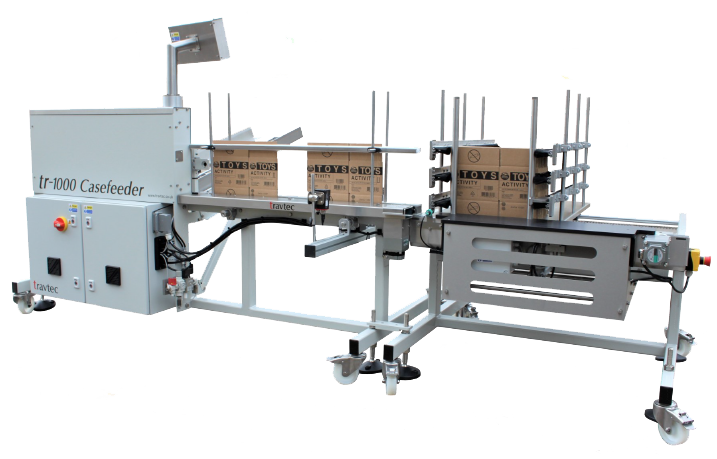

3. Introducing the CaseFeeder 2: Offline Coding Made Easy

The CaseFeeder 2 is an offline solution that addresses common pain points in case labeling and coding. Key features include:

- Versatile Case Handling: Designed to feed and transport a variety of case sizes and materials, making it simpler to manage multiple SKUs.

- Robust Build Quality: Built for longevity, which translates to less downtime and maintenance.

- User-Friendly Interface: Operators can quickly adjust settings and ensure consistent print quality for every run.

- Efficient Throughput: Despite being an “offline” system, the CaseFeeder 2 doesn’t compromise on speed. It’s capable of high throughput to match your production or warehousing needs.

4. Key Benefits of Offline Labelling for Your Business

- Scalability: Start small and scale up as demand grows. The CaseFeeder 2’s modular design and adaptable features let you expand without massive overhauls.

- Cost-Efficiency: By eliminating the need for additional on-line hardware or extensive conveyor modifications, offline coding can be more budget-friendly in the long run.

- Minimal Downtime: You can run maintenance, re-tooling, or testing on your offline system without halting your main production line.

5. Optimizing Your Workflow

To get the most out of an offline coding system like the CaseFeeder 2, consider the following best practices:

- Plan Your Batches: Group similar SKUs or case sizes together to reduce setup changes.

- Train Your Team: Ensure operators understand how to load, adjust, and troubleshoot the system.

- Integrate With Inventory Systems: Link labeling data to your warehouse management software for up-to-the-minute stock visibility.

- Schedule Routine Maintenance: Proactively maintain the system to avoid unplanned downtime.

Ready to Take Control of Your Stock?

By shifting to an offline strategy for case labeling and coding, you empower your production team to be more flexible, efficient, and accurate—leading to better stock control, fewer errors, and happier customers. The CaseFeeder 2 offers a robust, user-friendly solution that can seamlessly integrate into your existing workflow.